ABS/美国英力士/H950

“ABS/美国英力士/H950”参数说明

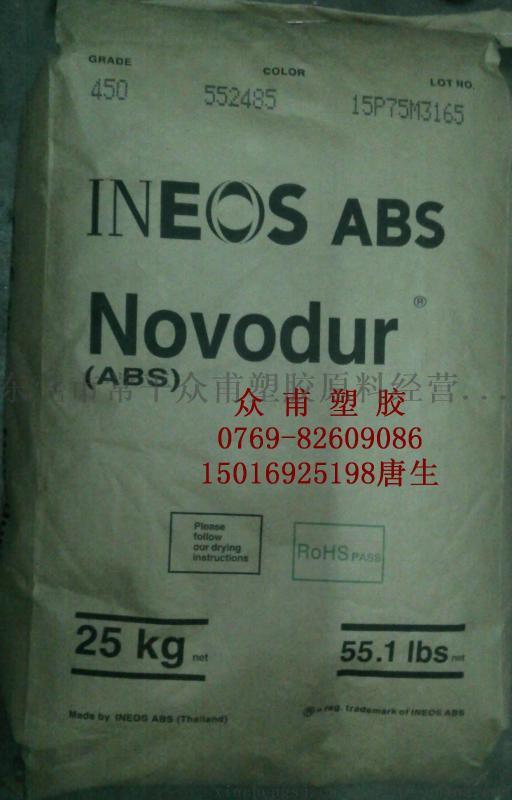

| 是否有现货: | 是 | 种类: | ABS |

| 加工方式: | 注塑 | 型号: | H950 |

| 商标: | INEOS | 包装: | 25千克/包 |

“ABS/美国英力士/H950”详细介绍

其他

产品属性:

| 所属类目:塑料橡胶 >> 塑料原料 >> 通用塑料原料 >> ABS H950 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 规格级别: | |

外观颜色: | |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 该料用途: | |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 备注说明: | ; | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ABS H950产品参数表: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

其他

| ABS | 英力士(INEOS) | Lustran | 448 | Injection molding grade of ABS with high impact, high gloss and improved toughness versus Lustran ABS 248; Complies with FDA regulation 21 CFR 181.32 for repeated-use food-contact applications in certain colors |

| ABS | 英力士(INEOS) | Lustran | 451 | Injection molding grade of ABS with medium impact and high gloss, designed with a unique balance of impact, heat resistance, flow and gloss for major appliance applications; Complies with FDA regulation 21?CFR 181.32 for repeated-use food-contact applications in certain colors |

| ABS | 英力士(INEOS) | Lustran | 488 | Injection molding grade of ABS with medium-to-high impact and very high gloss, offering a good balance of physical properties including very good moldability and improved surface aesthetics |

| ABS | 英力士(INEOS) | Lustran | 552 | Extrusion grade of ABS with medium gloss and medium impact; Designed to be used alone or blended with higher impact ABS for profile extrusion or substrate coextrusion |

| ABS | 英力士(INEOS) | Lustran | 556 | Extrusion grade of ABS with very low gloss and medium impact grade; Designed to be used alone or extruded over Lustran ABS 752 |

| ABS | 英力士(INEOS) | Lustran | 620 | High modulus, HFC 134a and HCFC 22 resistant extrusion grade of ABS designed for refrigerator door and food liners; Offers good melt strength and deep draw formability for superior material distribution in large complex parts |

编辑:西安常平众甫塑胶原料经营部 时间:2018/05/11